We thought we’d share how supply and demand work on farms like ours.

You probably know we primarily raise cattle in addition to chickens, turkeys, hogs, sheep, and goats. We treat our animals well and manage their lives and environment in the most natural way possible.

Each of those animals will provide us with high-quality meat to sell to you folks, our customers. The problem is that the amount varies from one cow to the next and is also different between cows, pigs, lambs, goats, turkeys, and chickens. The main reason for this is that every animal is a little different in size and shape. For example, the average steer is going to yield about 50% of its weight in retail cuts, while the average chicken is going to give you about 70% of its weight in retail cuts.

Each of those animals will provide us with high-quality meat to sell to you folks, our customers. The problem is that the amount varies from one cow to the next and is also different between cows, pigs, lambs, goats, turkeys, and chickens. The main reason for this is that every animal is a little different in size and shape. For example, the average steer is going to yield about 50% of its weight in retail cuts, while the average chicken is going to give you about 70% of its weight in retail cuts.

What makes these numbers important is that, based on the number of animals we have ready for production and the orders we have from customers who purchase in bulk, we have a somewhat limited supply of meat left to sell on a piecemeal basis. For example, you might have noticed we don’t sell chicken breast. The reason is that it’s almost impossible for us to sell the rest of the chickens on a regular basis. Yeah, every now and then people want wings or thighs, but breasts account for 60% or so of all chicken sales, and well, we’re just not Frank Purdue!

To be honest, this is one of the issues we have with the food supply chain in our country, and it’s a function of our “need it right now, disposable society.”

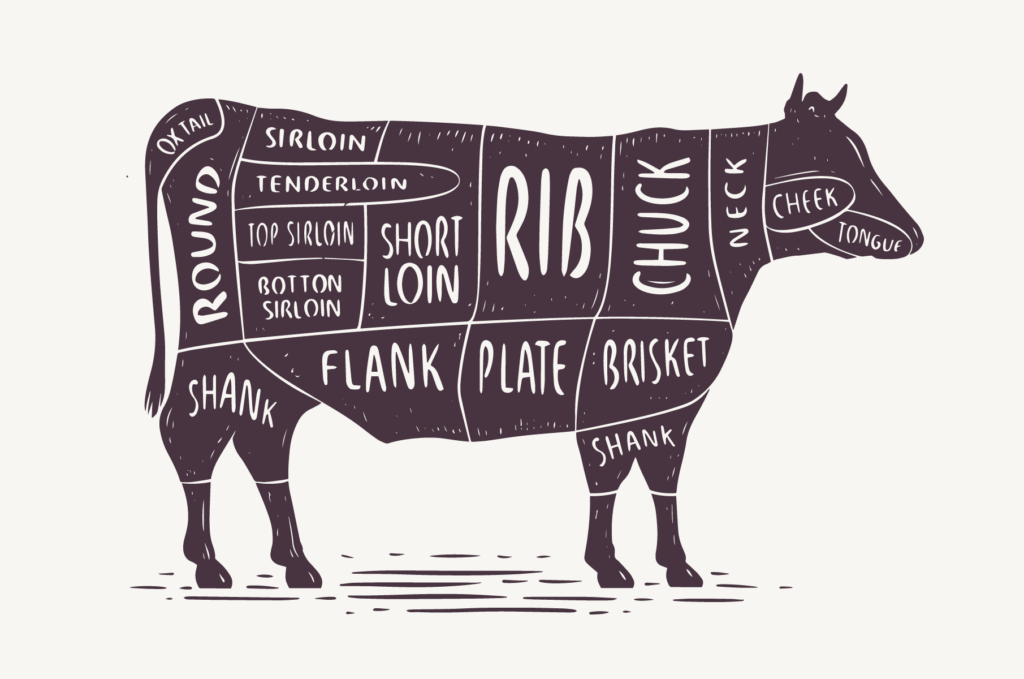

So this leaves farms like ours at the mercy of supply and demand. Sometimes we have more rib eyes, for example, than we can sell, and other times we just don’t have enough. For our smaller populations, like turkeys, for example, we sell out pretty consistently regardless of our sales forecasts. Clearly, if we run out of meat, you can be affected.

But the other way this can affect you is if you order a cut that we don’t have packaged, but may be in the production queue. In that case, it is going to take longer to deliver the meat you want at the quality level you expect.

There is a reason we don’t provide firm delivery dates on orders. We need to determine if we have the meat you ordered in stock, in the deep freeze at the production facility, or if it is already part of the production process. If it is the former, we deliver as quickly as we can. If it is the latter, it usually takes longer. These production issues and our ability to deliver a number of orders concurrently – which is one of the only ways we can provide free delivery – are why you’ll find it sometimes takes longer to receive your order than either of us would like.

We hope this helped you to understand the process a little better and that you agree that quality trumps immediacy. And if you don’t, you know where to reach us. 😉

Repeat customers have consistently told us it is more important to know where their food comes from than to get immediate delivery.